Carbide Moulder Knives

Request Quote

Hero Request Form

Experience Precision With Carbide Moulder Knives

Are you looking into purchasing some moulder knives? At Hot Knives, we understand the importance of precision and quality in your woodworking projects. That's why we offer two-piece carbide knife systems and corrugated inlaid carbide knives, designed to provide the accuracy and high-quality finish you need.

At Hot Knives, we're serious about supplying the carbide moulder knives you need at excellent prices. Call (314) 963-3322

today to take advantage of our fast turnaround times and to request a free quote.

Benefits of Using Carbide Moulder Knives

- Two-piece carbide knife sets (BakPak, SuperPac, Knife-Loc) are available either as wire EDM-cut (roughed-out) or finish-ground (ready-to-run)

- We apply wire EDM-cut side-clearance at the finish-grind using the finishing wheel

- Wire EDM-cut pair of carbide-tipped (inlaid) knives for tongue and vee-groove

- We provide these as a “roughed-out” knife needing (recommending) a light, quick finish-grind

- Finish-ground pair of carbide-tipped (inlaid) knives for tongue and vee-groove

Upgrade the tools in your toolroom with high-quality carbide moulder knives from Hot Knives. Contact us today for a free quote by

completing our online form, and we'll get back to you with a free quote quickly!

Why Choose Our Carbide Moulder Knives?

Our carbide moulder knives offer a range of benefits, including:

- Accuracy: Our knives are made to your machine's parameters, ensuring a perfect fit and precise cuts every time

- Quality: We're committed to providing excellent-quality products, so you can trust our knives to deliver a high-quality finish on your wood

- Cost-Effectiveness: Our competitive pricing means you get top-quality knives without breaking the bank

- Fast and Simple: With our fast turnaround times and simple ordering process, getting the knives you need has never been easier

- Experience: With over 20 years of service to the woodworking industry, we've supplied thousands of knife sets and built a reputation for reliability and expert service

- Shipping Upgrades: We offer a free UPS 2nd day air upgrade on finish-ground knife orders over $150.00 (net)

Carbide moulder knives don’t get any easier than this! Contact Hot Knives today to take advantage of our 1-2-day shipping times.

The Importance of Carbide Moulder Knives in Woodworking

In today’s woodworking industry, precision isn’t just preferred—it’s required. Whether you’re a custom furniture maker, a cabinetry professional, or part of a large-scale manufacturing operation, the sharpness, durability, and accuracy of your tooling directly impact the quality of your finished work.

Unlike standard steel knives, carbide options provide longer-lasting sharpness, greater resistance to wear, and more consistent performance across long production runs. This means fewer knife changes, less downtime, and smoother, cleaner finishes. For shops that deal with high-volume production or particularly hard woods, carbide is not just a smart choice—it’s often the only choice that ensures efficiency and reliability.

What Makes Carbide Moulder Knives Different?

Carbide is known for its toughness and wear resistance, making it a superior material for cutting tools. When used in a moulder knife, it provides a combination of durability and precision that standard high-speed steel cannot match.

Here are a few reasons carbide moulder knives stand out:

- Extended Tool Life – Carbide-tipped knives hold an edge significantly longer than steel, reducing the need for frequent sharpening

- Cleaner Cuts – Because carbide stays sharper longer, it produces smoother surfaces with fewer imperfections

- Reduced Downtime – Fewer knife changes mean machines can stay running longer without interruption

- Versatility – Carbide knives are effective on both softwoods and hardwoods, as well as composites

- Cost Savings Over Time – While the upfront investment is slightly higher, the extended lifespan of carbide knives results in lower overall tooling costs

In short, carbide moulder knives are built for professionals who need consistent, high-quality results without constant maintenance.

Applications of Carbide Moulder Knives

Because of their strength and cutting efficiency, carbide moulder knives are used across a wide variety of woodworking applications. Some of the most common include:

- Custom Millwork – Perfect for creating decorative trims, moldings, and architectural profiles

- Cabinetry – Achieve crisp, precise cuts for cabinet doors, frames, and drawer fronts

- Furniture Production – From simple edges to complex profiles, carbide knives ensure consistent results in furniture manufacturing

- Flooring – Carbide knives can handle the repetitive cutting needed for tongue-and-groove hardwood flooring

- Specialty Projects – Custom profiles for restoration or unique design elements are possible thanks to carbide’s durability

In each of these applications, carbide moulder knives help ensure that the final product meets both aesthetic and structural standards.

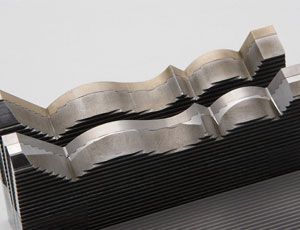

Two-Piece Carbide Knife Systems Explained

One of the popular options offered by Hot Knives is the two-piece carbide knife system. These systems, including BakPak, SuperPac, and Knife-Loc, are designed for flexibility and convenience.

- Wire EDM-Cut Knives – These are roughed out to shape and require only a light finish grind before use

- Finish-Ground Knives – Ready-to-run options that save even more time by arriving fully prepared for installation

This flexibility allows woodworking shops to choose the option that best matches their workflow. For example, shops with their own finishing equipment may opt for roughed-out knives, while those looking for immediate usability often select finish-ground knives.

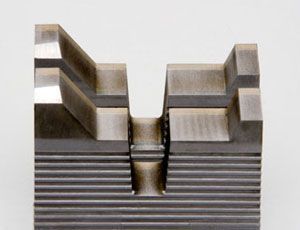

Inlaid Carbide Moulder Knives

Another powerful option is the inlaid carbide knife. These knives are crafted with a carbide cutting edge fused into a steel body, combining the durability of carbide with the resilience of steel.

Advantages of inlaid knives include:

- Long-lasting cutting edge

- Reduced sharpening frequenc

- Strong structural support from the steel bas

- Availability in custom profiles for specialized project

Hot Knives provides both roughed-out and finish-ground versions of inlaid carbide knives, making it easy to choose the level of preparation that works best for your shop.

Efficiency and Cost Savings

For many woodworking businesses, the decision to switch to carbide moulder knives comes down to efficiency. Although they may cost slightly more initially, their extended lifespan quickly offsets the upfront expense. In fact, most shops find that carbide knives pay for themselves by reducing labor costs, minimizing downtime, and eliminating the need for frequent resharpening.

Consider this example: A shop producing hundreds of feet of molding per day with steel knives may need to stop multiple times to change or sharpen dull blades. With carbide knives, those interruptions are drastically reduced, allowing more continuous production and better use of labor hours. Over weeks and months, these time savings add up to significant cost reductions.

Customization for Your Shop’s Needs

At Hot Knives, we understand that no two shops are alike. That’s why we offer custom carbide moulder knives designed specifically to meet your machine’s parameters and your project’s requirements. Using CAD design and advanced cutting technology, we can create knives for virtually any profile.

This means whether you’re replicating historical moldings for a restoration project or developing a unique profile for a client’s custom order, Hot Knives can deliver. Best of all, there are no extra charges for custom designs—every project is given the same level of precision and care. Ready to get started on creating custom

moulder knives for your needs? Contact us today.

Purchase Quality Carbide Moulder Knives Today

At Hot Knives, we provide only high-quality carbide moulder knives. With our nationwide delivery, years of expertise, and commitment to quality, we're the tool and die makers you can trust. Don't wait - get in touch with us today to experience the precision and quality of our carbide moulder knives.

2-pc Carbide Knife System - Front knife is finish-ground with a 280-grit diamond wheel on our CNC grinder. Rear knife is wireEDM-cut only - very close to finished.

WireEDM-cut Inlaid Carbide

Reviews

Related Services

Learn More About

Hot Knives

Serving the United States. Hot Knives specializes in corrugated moulder knives, rosette knives, shaper knives, and CBN grinding wheels. 1–2-day shipping. Nationwide delivery. Custom orders welcome. Call for a free same-day quote.

Share On: